A lift is a power-driven, persistent moving stairway

intended to transport travelers all over short vertical separations. Lifts are

utilized the world over to move person on foot activity in spots where lifts

would be unreasonable. Main zones of use incorporate malls, air terminals,

travel frameworks, exchange focuses, inns, and open structures. The advantages

of lifts are numerous. They have the ability to move huge quantities of

individuals, and they can be put in an indistinguishable physical space from stairs

would be. Each Escalator Parts acts and performs different significant roles.

The top stage contains the engine get together and the

principle drive outfit, while the base holds the progression return idler

sprockets. These areas likewise stay the closures of the elevator truss.

Moreover, the stages contain a story plate and a brush plate. The floor plate

gives a place to the travelers to remain before they step onto the moving

stairs. This plate is flush with the completed floor and is either pivoted or

removable to permit simple access to the apparatus beneath. The brush plate is

the piece between the stationary floor plate and the moving stride. It is so

named on the grounds that its edge has a progression of spikes that look like

the teeth of a brush. These teeth work with coordinating spikes on the edges of

the means. This plan is important to minimize the crevice between the stair and

the arrival, which keeps objects from getting got in the hole. The truss is an

empty metal structure that extensions the lower and upper arrivals. It is made

out of two side segments combined with cross supports over the base and just

underneath the top. The finishes of the truss are connected to the top and base

landing stages by means of steel or solid backings.

The truss conveys all the straight track areas

interfacing the upper and lower segments. The means themselves are strong,

one-piece, kick the bucket cast aluminum. Elastic mats might be appended to

their surface to lessen slippage, and yellow division lines might be added to

obviously demonstrate their edges. The main and trailing edges of every

progression are cleated with brush like projections that work with the brush

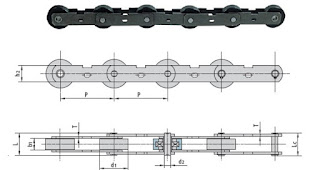

plates on the top and base stages. The means are connected by a nonstop metal

chain so they shape a shut circle with every progression ready to twist in

connection to its neighbors. The front and back edges of the means are each

associated with two wheels. The back wheels are separate further to fit into

the back track and the front wheels have shorter axles to fit into the smaller

front track. As depicted over, the position of the tracks controls the

introduction of the means. The railing gives an advantageous handhold to

travelers while they are riding the elevator. On top of pressure part is the

internal development segments, which are made of synthetically treated elastic,

intended to keep the layers from isolating. At long last, the external layer,

the main Escalator Parts that travelers really observe, is the elastic cover, which is a

mix of manufactured polymers and elastic.

This cover is intended to oppose debasement from natural

conditions, mechanical wear and tear, and human vandalism. The railing is built

by sustaining elastic through a PC controlled expulsion machine to deliver

layers of the required size and sort so as to match particular requests. The

part layers of texture, elastic, and steel are formed by gifted laborers before

being nourished into the presses, where they are combined. Whenever introduced,

the completed the process of railing is pulled along its track by an anchor

that is associated with the principle drive adapt by a progression of pulleys.